New catalyst makes plastic upcycling 10x more efficient than platinum

Many common products, including plastics and detergents, rely on chemical reactions that depend on catalysts made from precious metals

Many common products, including plastics and detergents, rely on chemical reactions that depend on catalysts made from precious metals such as platinum. These metals are effective but costly and limited in supply. For years, scientists have been searching for alternatives that are cheaper and more sustainable. One promising option is tungsten carbide, an Earth-abundant material already widely used in industrial machinery, cutting tools, and chisels.

Despite its potential, tungsten carbide has not been easy to use as a catalyst. Its chemical behavior can be unpredictable, which has restricted its broader adoption. Researchers led by Marc Porosoff, an associate professor in the University of Rochester’s Department of Chemical and Sustainability Engineering, have now made important progress that could allow tungsten carbide to compete with platinum in key chemical reactions.

Why Atomic Structure Matters

According to Sinhara Perera, a chemical engineering PhD student in Porosoff’s lab, one of the main challenges lies in how tungsten carbide atoms arrange themselves.

Tungsten carbide’s atoms can form many different configurations, known as phases, says Perera. These phases can strongly influence how well the material performs as a catalyst.

“There’s been no clear understanding of the surface structure of tungsten carbide because it’s really difficult to measure the catalytic surface inside the chambers where these chemical reactions take place,” she says.

To address this problem, the research team designed a method to precisely control the structure of tungsten carbide during active reactions. In a study published in ACS Catalysis, Porosoff, Perera, and chemical engineering undergraduate student Eva Ciuffetelli ’27 manipulated tungsten carbide particles at the nanoscale inside chemical reactors that operate at temperatures above 700 degrees Celsius.

Using a technique called temperature-programmed carburization, the researchers created tungsten carbide catalysts in specific phases directly inside the reactor. They then ran chemical reactions and analyzed which versions delivered the strongest performance.

“Some of the phases are more thermodynamically stable, so that’s where the catalyst inherently wants to end up,” says Porosoff. “But other phases that are less thermodynamically stable are more effective as catalysts.”

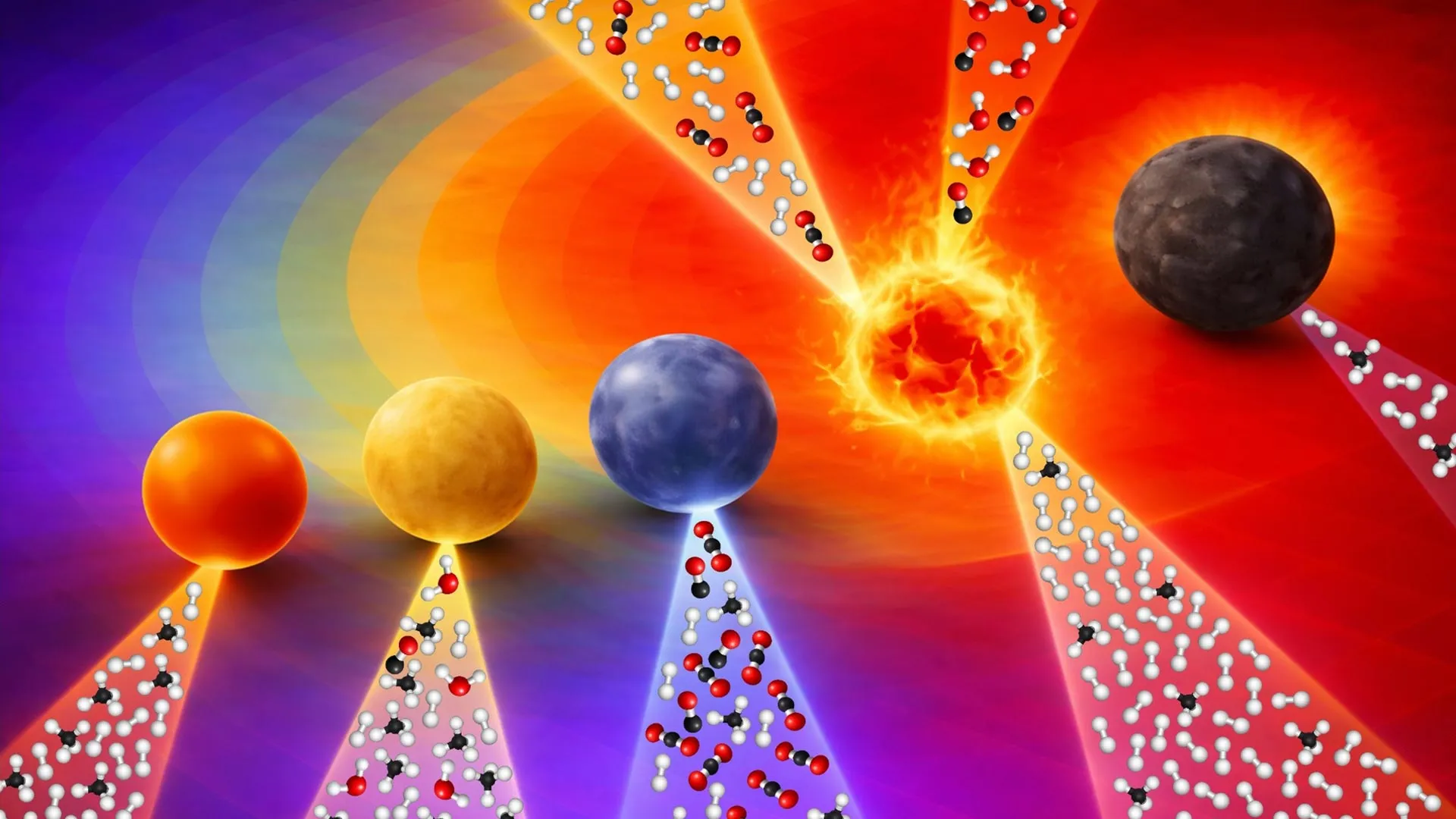

The team identified one phase in particular, β-W2C, that showed exceptional performance in reactions that convert carbon dioxide into key building blocks for fuels and useful chemicals. With additional optimization by industry, the researchers believe this form of tungsten carbide could match platinum’s effectiveness without its high price or supply limitations.

Turning Plastic Waste Into New Materials

Beyond carbon dioxide conversion, Porosoff and his collaborators have also explored tungsten carbide as a catalyst for recycling plastic waste. Their work focuses on upcycling, a process that transforms discarded plastics into higher-value products rather than lower-grade materials.

In a study published in the Journal of the American Chemical Society, led by Linxao Chen from the University of North Texas and supported by Porosoff and University of Rochester Assistant Professor Siddharth Deshpande, researchers demonstrated how tungsten carbide can drive a chemical process known as hydrocracking.

Hydrocracking breaks large molecules into smaller ones that can be reused to make new materials. In this case, the team targeted polypropylene, which is used in water bottles and many other plastic products.

While hydrocracking is common in oil and gas refining, applying it to plastic waste has proven difficult. The long polymer chains in single-use plastics are extremely stable, and contaminants in waste streams can quickly deactivate traditional catalysts. Platinum-based catalysts also rely on microporous structures that are too small for large plastic molecules to enter, limiting their effectiveness.

“Tungsten carbide, when made with the correct phase, has metallic and acidic properties that are good for breaking down the carbon chains in these polymers,” says Porosoff. “These big bulky polymer chains can interact with the tungsten carbide much easier because they don’t have micropores that cause limitations with typical platinum-based catalysts.”

The results were striking. Tungsten carbide was not only far less expensive than platinum catalysts, but it was also more than 10 times as efficient in hydrocracking plastic waste. Researchers say this approach could open new pathways for recycling plastics and advancing a circular economy where materials are continuously reused.

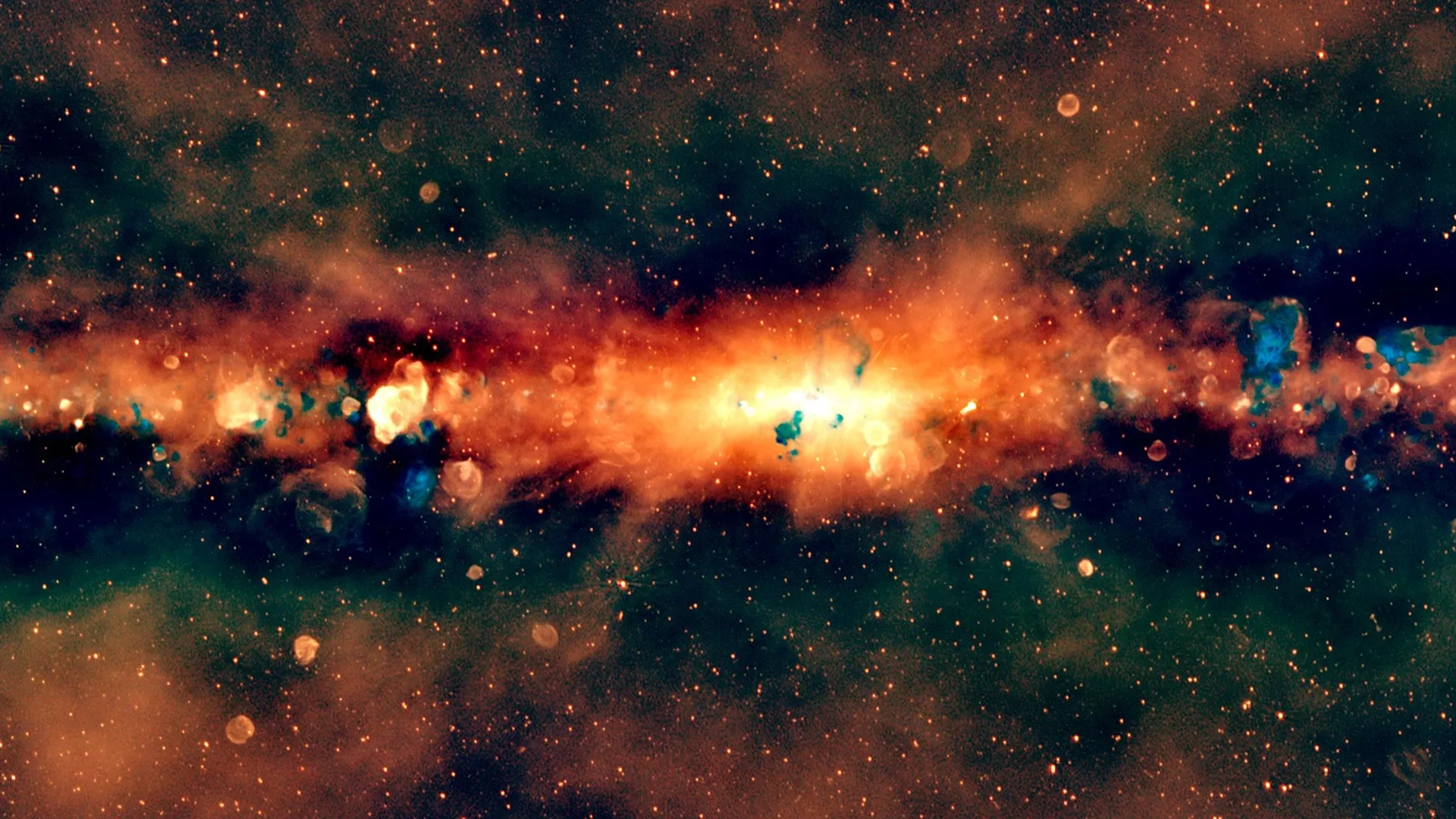

Measuring Heat Where It Matters

A key factor behind these advances is the ability to precisely measure temperature on catalyst surfaces. Chemical reactions either absorb heat (endothermic) or release heat (exothermic), and managing temperature is critical for efficiency. Many industrial processes rely on multiple reactions occurring together, making accurate temperature control even more important.

Current temperature measurement methods provide only rough averages, which can hide critical variations at the catalyst surface. This lack of precision makes it difficult to fully understand and reproduce catalytic behavior.

To solve this problem, the research team adopted optical measurement techniques developed in the lab of Andrea Pickel, a visiting professor in the Department of Mechanical Engineering. In a study published in EES Catalysis, they described a new method for directly measuring temperatures inside chemical reactors.

“We learned from this study that depending on the type of chemistry, the temperature measured with these bulk readings can be off by 10 to 100 degrees Celsius,” says Porosoff. “That’s a really significant difference in catalytic studies where you’re trying to ensure that measurements are reproducible and that multiple reactions can be coupled.”

Using this technique, the team examined tandem catalyst systems in which heat released by one reaction drives another reaction that requires heat input. Better matching these reactions can reduce wasted energy and improve overall efficiency.

Porosoff says the method could influence how catalysis research is conducted more broadly, encouraging more accurate measurements, stronger reproducibility, and more reliable results across the field.

Funding and Support

The ACS Catalysis study was supported by the Sloan Foundation and the Department of Energy. The Journal of the American Chemical Society research received funding from the National Science Foundation. The EES Catalysis study was funded by the New York State Energy Research and Development Authority through the Carbontech Development Initiative.